Our Partner:

Rio Resources, LLC Wastewater Technology

Proprietary Technology for Municipal Waste Treatment

Rio Resources LLC (Founded 2012)

- Dale R. Yates, Founder, President, and CEO

- Bachelor Business and Administration NTU

- USMC and Vietnam Veteran

- 40 yrs Water and Wastewater Management Experience

- 10 yrs Municipal Management

- Charles R. Blank, Co-Founder, Director

- Mechanical Engineer TAMU

- Business leader and Entrepreneur, San Antonio

Rio Resources Overview

• Corporate Office

• New Braunfels, Texas

• Operations

• SRS Entrada- Midland, Texas

• O&G Waste Treatment, Water sales and Technology Development

• Municipal and Industrial Waste and Water Treatment

- Intellectual Property

- US Patent 10,724,314

- US Patent 11,001,518

- US Continuation Application: 17/315,858 Filed 2021

- PCT Application PCT/US21/17955 Filed 2021

Rio Corporate Technical Support

Technical Services Team

David Googins, Petroleum Engineer

Hunt, Guillot & Associates, LLC- Engineering

CelaCare Technologies, Inc. and CelaCare Analytical Services, LLC

Kenneth Yates, Biologic and Process Specialist

Brenna Adolph, Consulting Chemical and Process Engineer

Select Vendors Microbiological, Chemistry and Engineering Support Activities

Rio Resources Advancing Wastewater Treatment

Rio Resources Technology for Improved Municipal Wastewater Management

Rio Objectives

Opportunity for Conservation of Resources

- Proprietary Primary Treatment

- Equalization of Flow and Solids Stabilization

- Biodigester/Clarification

- Repurpose solids for land application

- Repurpose municipal wastewater to stream and irrigation standards meeting State and EPA standards

- Provide opportunity to repurpose to potable standards

- Reduce Costs

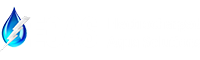

Process Technology

Technology Advantages

- Recycle Wastewater for Industrial or Public Reuse

- Reduce Energy Requirement and Operational Costs

- Green Bio-Engineered Process

- Anaerobic with Aerobic MBBR Biodigestion

- 100nM Ceramic Ultrafiltration

- Train System allowing Redundacy (125,000 GPD/Train)

- Environmentally Friendly

- Small Footprint for Less Cost Containment

- Capital and Operational Cost Effective

Wastewater Process (100,000 GPD/Train)

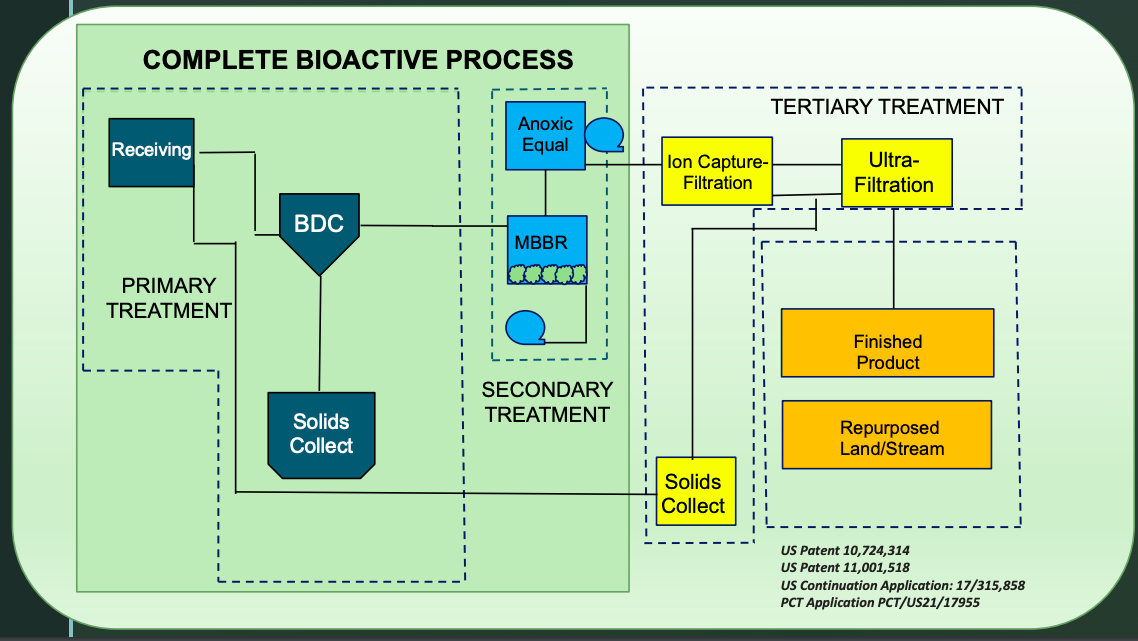

Activated Bio-digester/Clarifier (Primary Treatment)

• Flow Equalization

• Sludge Management and Stabilization

• Clarification

• Anaerobic Digestion

• Anoxic Effluent to MBBR

MBBR Aeration (Secondary Treatment)

• Aerobic Biological Treatment

• Consumes Organics

• Removal of BOD/COD

Coarse/Fine Filtration (Tertiary Treatment)

- Engineered Activated Filter Media (AFM®)

- 1 micron Filtration

- Negatively Charged Glass

- Media for Cationic Ion Capture

- Resists Biofouling and Biocoagulation

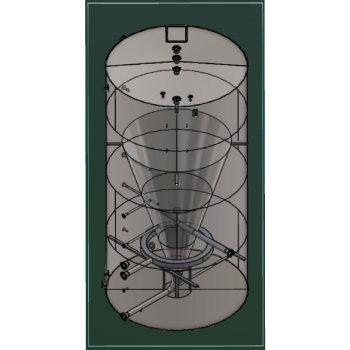

Ultressa Cerafiltec (Tertiary Treatment)

- Ceramic Microfiltration Membrane System

- 100-nanometer Ceramic Membranes

- Removal of Bacteria, Micro-plastics and Many Viruses and Toxins

Summary

- Defined Green Engineered Process for Repurposing for Industrial or Municipal Reuse

- 125,000 GPD Train System Allowing for Straight-forward Expansion

- US Patent Protected with Continuation and PCT Patents Pending

- Small Footprint Allowing for Cost Effective State Containment Requirements

- Process Technology Provides Significant Advantages in CapEx and Operational Costs Over Current Methodologies